Stainless steels are a family of corrosion-resistant steels that contain at least 10.5% of chromium. Apart from chromium, these steels are commonly alloyed with nickel, molybdenum, titanium, niobium and other elements.

Their mechanical properties and application depend on their chemical composition. The durability and serviceability of a manufactured product depends on a careful choice of the right grade of steel.

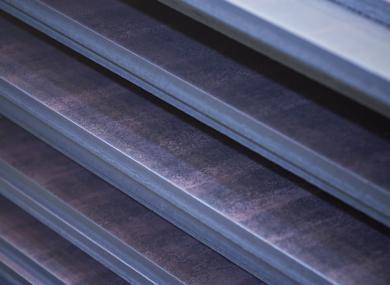

Martensitic stainless steels

are not as corrosion-resistant as the other two classes but are extremely strong and tough, as well as highly machinable, and can be hardened by heat treatment. Martensitic stainless steel contains chromium (12–14%), molybdenum (0.2–1%), nickel (less than 2%), and carbon (about 0.1–1%). It is quenched and magnetic. Special precipitation hardening martensitic stainless steels can also be produced by alloying copper. They provide an outstanding combination of high strength, good corrosion resistance, and good mechanical properties at temperatures up to 300 °C.

Applications:

- chemical and petrochemical industry,

- energy sector,

- transportation,

- aerospace,

- oil and gas,

- architectural/ civil engineering,

- medical,

- food and water processing.

SALES SIJ ACRONI

- SIJ ACRONI

- Cesta Boris Kidriča 44

4270 Jesenice, Slovenija - Lat: 46.422984 | Long: 14.096365

- +386 4 584 1422

- sales@acroni.si www.acroni.si